Mixing 101: 4 Impeller Types & Their Applications

The Importance of Impeller Selection

We first mentioned impellers in our blog discussing 4 factors for configuring your mixer. In this post, we will look more closely at impeller types and their applications.

The impeller is the component of a mixer that does the actual mixing and produces the results. That’s because when it rotates, it creates fluid flow and shear patterns. While there are many types of impellers, there are 4 main types we use when engineering mixers.

The 4 Main Impeller Types

1. Airfoil

Generally most efficient because it produces the maximum pumping with the lowest shear.

|

|

| Standard Dynaflow™ | High Solidity Dynaflow™ for Gas Dispersion |

2. Pitch Blade

Ideal for viscous mixtures and for applications requiring a combination of pumping and shearing.

|

|

| Standard Pitch P4 | Modified High Efficiency Pitch |

3. Radial Blade

Ideal for applications where shear is the primary requirement, or where agitation close to the bottom of the tank is desired.

|

| Radial Blade |

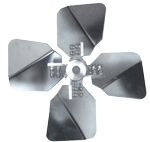

4. Marine-Type Propellers

Ideal for low-viscosity, high-speed direct drive mixers.

|

| Propeller Blade |

Summary

The mixer you need depends on your process and the chemicals you use in that process. If you’re interested in learning more about mixing solutions for your process, post a comment or email us at info@dynamixinc.com.