Open. Closed. Universal.

Maximum Mount Flexibility

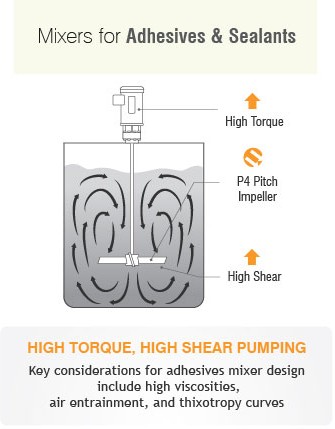

When Mixing Adhesives and Sealants

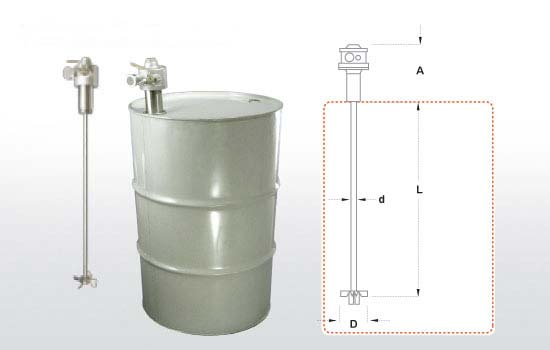

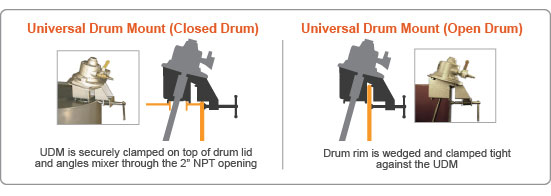

Dynamix’s innovative “Universal Drum Mount” (UDM) makes the drum mixer both versatile and portable when mixing adhesives and sealants. Specially designed to mount on both open-head or closed-head drums, it can be used on multiple tank types in different areas of a plant, giving you unparalleled flexibility in a single drum mixer.

- Clamp Mount

- 2″ NPT Bung Mount

- Drum Lid Mount

- Universal Drum Mount (UDM)

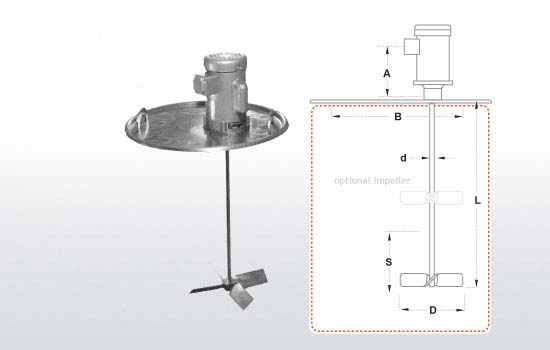

Collapsible Impellers

Big Tank Mixing in a Drum When Mixing Adhesives and Sealants

Our 4-bladed collapsible impellers allow blades up to 8″ in diameter to enter through the small openings of a barrel or drum and create the controlled mixing environment you expect from larger mixers. Adhesive and sealant product quality, mixer performance, and energy efficiency increase with a properly sized impeller.

- Pitch

- Radial

- Dynaflow ™ Airfoil

- Fixed or Collapsible

The Right Drum Mixer

For Your Adhesive and Sealant Mixing Application

At Dynamix, we provide you with a solution, not just a mixer. The difference? We consider your product and process for making adhesives and sealants, and environment, and then size a mixer for maximum performance and efficiency. Our drum mixers can ensure the quality of your product, no matter the industry or application:

- Paints & Coatings

- Sealants & Adhesives

- Inks & Dyes

- Chemicals

- Polymers

- Polyurethane

- And Many More…