Open. Closed. Universal.

Maximum Mount Flexibility When Mixing Paint

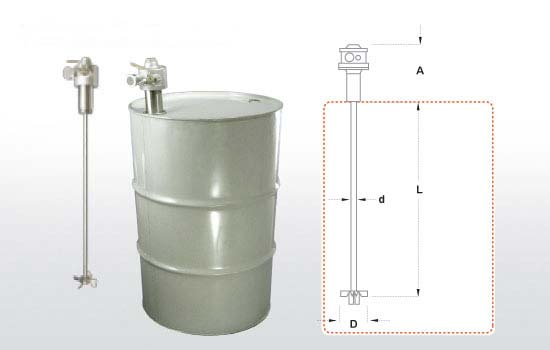

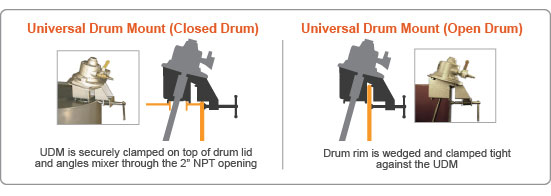

Dynamix’s innovative “Universal Drum Mount” (UDM) makes the drum mixer both versatile and portable when mixing paint. Specially designed to mount on both open-head or closed-head drums, it can be used on multiple tank types in different areas of a plant, giving you unparalleled flexibility in a single drum mixer.

- Clamp Mount

- 2″ NPT Bung Mount

- Drum Lid Mount

- Universal Drum Mount (UDM)

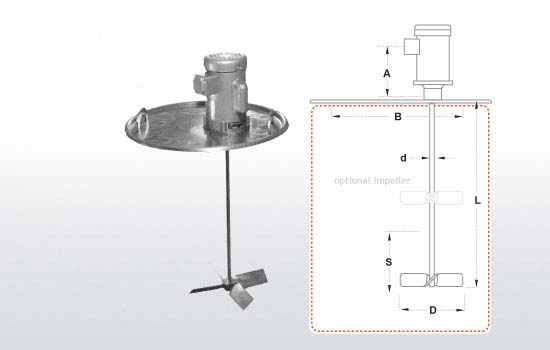

Collapsible Impellers

Big Tank Mixing In A Drum When Mixing Paint

Our 4-bladed collapsible impellers allow blades up to 8″ in diameter to enter through the small openings of a barrel or drum and create the controlled mixing environment you expect from larger mixers. Paint product quality, mixer performance, and energy efficiency increase with a properly sized impeller.

- Pitch

- Radial

- Dynaflow ™ Airfoil

- Fixed or Collapsible

The Right Drum Mixer

For Your Paint Mixing Application

At Dynamix, we provide you with a solution, not just a mixer. The difference? We consider your paint product, process, and environment, and then size a mixer for maximum performance and efficiency. Our drum mixers can ensure the quality of your product, no matter the industry or application:

- Paints & Coatings

- Sealants & Adhesives

- Inks & Dyes

- Chemicals

- Polymers

- Polyurethane

- And Many More…