POLYMER MIXERS FOR TOTE TANKS & DRUMS

Quality Control With Polymer Mixing Equipment

Polymers are used across many applications such as effluent treatment and many industries, including wastewater and water, oil and gas, paints and coatings, and adhesives and sealants. Like all mixtures, polymers settle and stratify over time, which can make quality control and customer satisfaction a challenge.

Now, there are tools that can guarantee the quality of your polymer supply. From dry polymers to liquid emulsion polymers, Dynamix has a full line of industrial polymer mixers for each stage of your process.

CHOOSE THE DYNAMIX SERIES FOR YOUR TANK SIZE:

|  |  |  |  |

POLYMER MIXERS

Guaranteed For Your Process

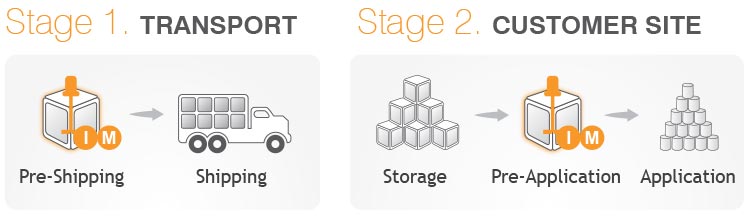

The uniformity of your polymers throughout your process has a direct impact on the quality of the finished product. For example, each step of the manufacturing process requires that polymers, color concentrates, and additives be mixed according to specifications to prevent stringers and fisheyes. Downstream, changes to your product during transport often mean it will need to be mixed back to uniformity. You need mixers that will bring your product to spec each step of the way.

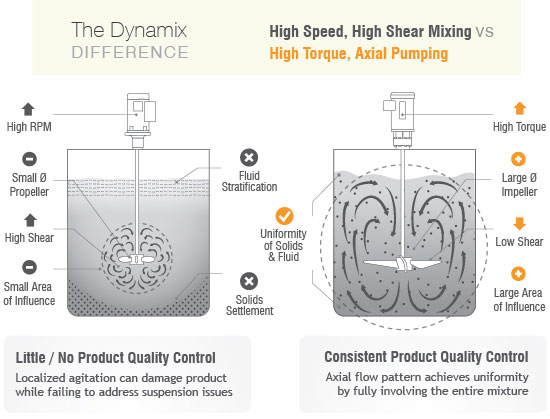

But here’s the challenge. It’s difficult to bring your product back to uniformity with traditional, high-speed mixers because they shear the product with high RPM (>350) impellers or conventional ones designed to create shear. In many instances, shear is a benefit to mixing, but not with polymers. High RPM mixers also create a non-directional, localized flow that can’t pull stratified particles down from the top or re-suspend solids from the bottom.

Keep Customers Satisfied With The Dynamix ITM Series Tote Mixer

How do you ensure that your polymers are up to spec even after they’ve left your hands? By delivering them with an Integrated Tote Mixer (ITM). Truly portable and easy to install, the ITM can go everywhere your tote goes. This means your polymers can be brought to spec anytime, anywhere.

| The ITM is designed to be set up by just one person, without the need for tools or brackets: |

The ITM is your Quality Control tool:

| |

POLYMER MIXING EQUIPMENT

Configured For Your Process

Dynamix’s polymer mixing experts will seek to understand your process, select the perfect mixer, and provide you with a complete mixing solution. By understanding your process, we’re able to configure agitators and mixers specifically for your wastewater treatment application. This in-depth knowledge is what also makes it possible for us to work with you to address your process and cycle time.

The result? Uniformity, right when you need it.