Dynamix agitators' cookie consent authorization

This website uses cookies to ensure you get the best experience on our website

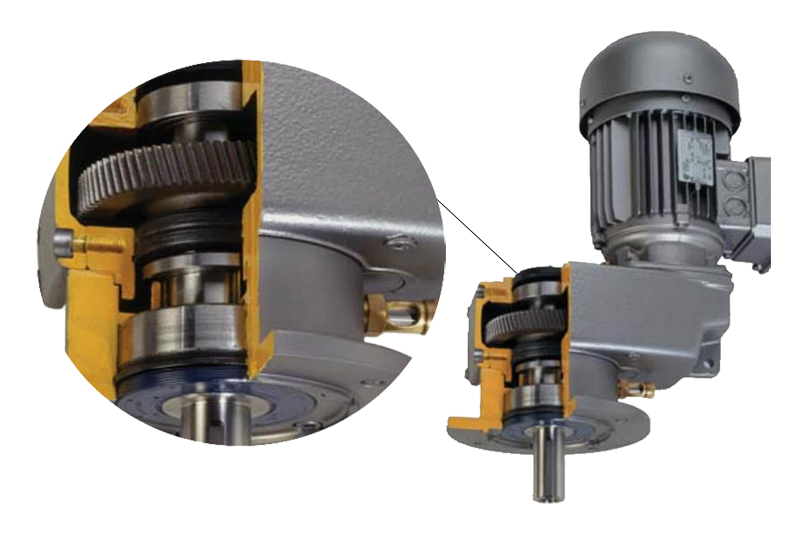

GMX 1-4 Helical Parallel Shaft Gearbox

Designed for high efficiency in large tanks, the GMX Series handles medium to heavy-duty applications. Large tanks (2,500 – 30,000 + Gallons) require the design integrity and control offered by our drive and shaft designs. This large tank mixer is available with design guarantees, and prompt supply.

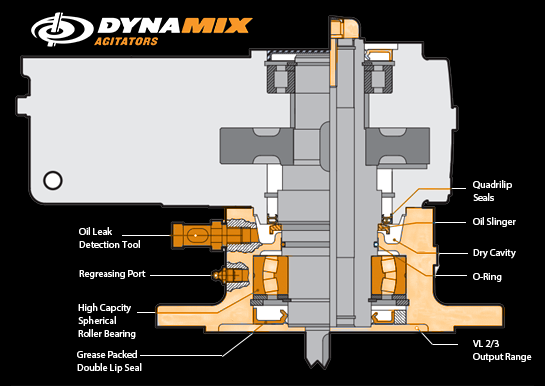

Precision gearboxes are critical to the operation and reliability of our mixer designs. Our drives are built on a one-piece case to ensure rigid and precise torque and shaft performance. Cases are machined in a single operation ensuring the long life and low maintenance of the sealing and bearings. Available in both helical and bevel helical gear configurations, our team can select and configure a mixer to suit your needs.

Contact Dynamix for specific certification details on each product component – available upon request, please contact us.

Oversized tapered roller bearings to manage overhung loads as calculated for your application and tank height. Increased capacity in either overhung (radial) or thrust (axial) loading ensures that premature bearing failure will not occur due to high stresses in the bearing elements. The increased bearing capacity optimizes the gearbox for mixing applications.

Full line of impeller options: pitch, radial, P3B radial flow, and our unique Dynaflow high-efficiency impeller.

Quality is assured at Dynamix. All gearboxes are manufactured and assembled based on, ISO 9001 standards. From close monitoring of incoming parts to manufacturing and assembly from the gearbox component provider.

Dynamix designs this product line according to your application and process. Our chemical and mechanical engineers come from various process industries and will work to understand and develop your design requirements.

Oil leakage protection with “dry cavity” designs is available to assure oil-safe operation. These are used as a redundancy to the seal at the oil sump and prevent oil leakage through the output flange

Don’t like filling out forms? No problem, send us an email directly info@dynamixinc.com

This website uses cookies to ensure you get the best experience on our website