Why Dynamix Focuses on Torque When Designing Mixers

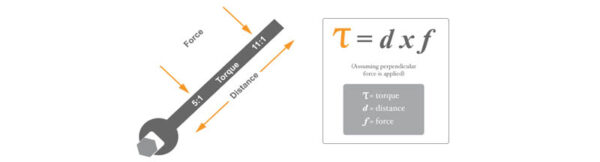

At Dynamix we focus on torque as opposed to horsepower when designing our mixers. Torque is a parameter which is preferable in mixing. By using larger diameter impellers and higher gear ratios, higher torque is produced, and more efficient mixing can be obtained. This can be done without using a high horsepower motor and high mixer speeds (RPM). What is torque and horsepower? Horsepower is equal to the RPM times Torque, divided by 5252. Therefore, lower RPM gives higher torque at the same power. A simple way to think about torque versus horsepower, is to imagine a Semi Truck and a Formula 1 racing car. These vehicles, the truck and car, are known to have the largest towing