Selecting Wastewater Mixers for Wastewater Treatment – Part 1

Wastewater Mixers for Optimal Chemical Preparation

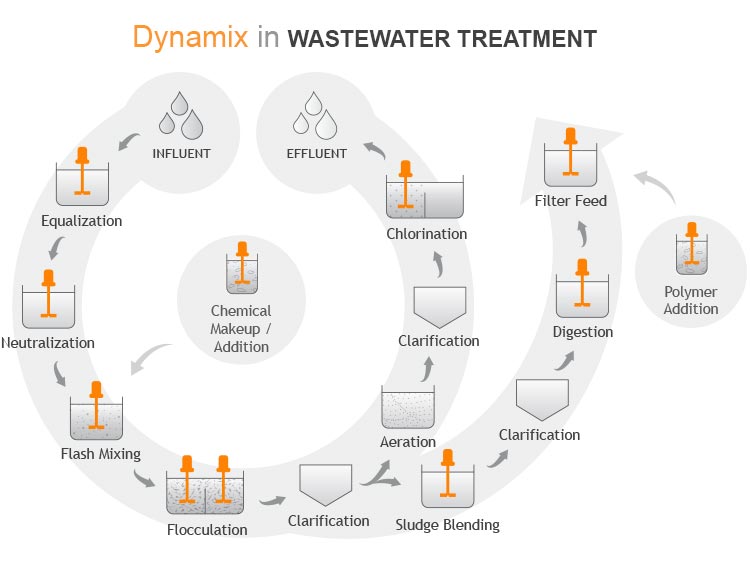

Chemical preparation in wastewater and water treatment directly impacts many downstream processes. Let’s take a look at several common chemicals used and some key factors that influence their preparation and the selection of wastewater mixers.

Lime Slurry Preparation

When preparing lime slurries for controlling pH, uniformity is critical. Why? Because lime solids must reach/stay in suspension if they are to serve their purpose in downstream processes. For this reason, it’s essential that wastewater and water treatment facilities have lime slurry mixers that can efficiently and effectively make up/maintain uniform slurries.

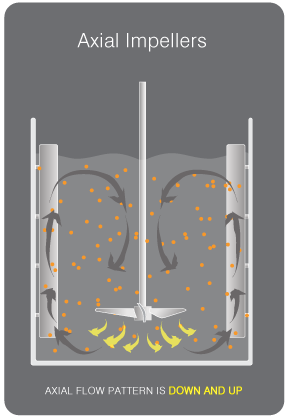

In order to successfully suspend/re-suspend solids, a mixer needs to create a flow pattern that involves the entire tank. Axial flow patterns have large areas of influence, so they’re very effective at pulling settled solids back into suspension. This slow, high torque mixing is especially important in high viscosity mixtures, like uniform slurries that contain up to 30% solids. Because the range of solids can vary, waste water mixers should be engineered to meet the unique needs of the slurry. Here are a few things to consider when selecting a mixing solution for lime slurry preparation:

Impeller Shape & Size

- Lime slurry mixers should have impellers with airfoil blades because they promote a long, laminar flow that maximizes the area of influence. The diameter of the impeller should also be customized to the tank: 0.3 to 0.5 impeller to tank diameter ratio would be optimal. While we have a full range of impeller types at Dynamix, we typically recommend our Dynaflow™ airfoil blade for lime slurry mixing.

Shaft Diameter & Design

- In any mixing solution, the mixer shaft should be engineered to prevent the destructive forces caused when critical speeds are reached. At Dynamix we design the shafts to operate 65% below the first critical speed: this is well below industry best practice, which is to stay at least 20% below the first critical speed. This minimizes shaft vibration and deflection.

Baffle, Tank & Ratio Design

- Optimized mixing doesn’t stop at the mixer. That’s why we recommend configuring the non-mixer components of your process, including baffle sizing and ideal tank selection.

Activated Carbon Slurry

Activated carbon slurries, which are used in wastewater and water treatment to remove organics for taste, odour, and colour control, have different requirements than other treatment chemicals. An activated carbon slurry mixer must be designed to perform 3 functions:

Wetting Out

Wetting Out

- Dry carbon particles tend to float: if they’re to be incorporated into the mixture, proper wetting during makeup is critical. As with lime slurry mixing, a mixer that generates an axial flow pattern will be most effective for mixing dry carbon. Carbon slurry particles tend to float, so they need to be “sucked” into the liquid from the surface. The axial flow impeller placed close to the liquid interface will provide the best mixing for wetting out the particles.

Suspension

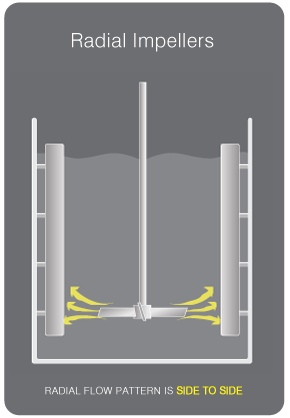

- Once the carbon particles have been wetted out, they need to be brought into

suspension. We recommend using a radial flow impeller. The impeller should also be positioned close to the tank bottom.

suspension. We recommend using a radial flow impeller. The impeller should also be positioned close to the tank bottom.

Re-suspension

- To keep activated carbon particles suspended, the process used when bringing them to suspension should be repeated continuously during storage until they are ready for use.

Polymer Mixing

Polymers are used in wastewater and water treatment to enhance flocculation by optimizing the strength, size and weight of flocs. Before they can be added to the flocculation process, the powder or neat forms of polymers need to be activated and aged.

Activation & Aging

Polymer activation is a complex process involving high speed, high shear mixing in a pump for liquid polymers and in an edductor for dry polymers. Top-entry mixers are used for polymer aging. Activated polymers can easily be damaged during the aging process. To protect them, we recommend using a low shear, high torque mixer and a low speed. A laminar flow pattern, like the one created from the Dynaflow™ airfoil impeller, protects the integrity of solids and maintains product quality. The pattern also creates less drag than a pitch blade, so it’s more efficient

Facilities that receive their polymers in totes have to prevent stratification. The solution for this job is a portable mixer that can be easily inserted into plastic totes. For our clients, we recommend the ITM. The collapsible impellers allow insertion of blades much larger than the small tote opening in order to generate the desired axial flow pattern.

Summary

The waste water mixer you need depends on your process and the chemicals you use in that process. If you’re interested in learning more about mixing solutions for your process, post a comment or email us at info@dynamixinc.com.