Having product separation and settlement challenges in your application or process?

These are key quality control issues for many Plant Managers, but mixers are rarely singled out as the source of the problem. This is partly due to the inability to see into the tank, and part a common belief that mixers are a “Black Art”.

At Dynamix, we take a controlled scientific approach to mixer design. With this as a basis for discussion, we optimise the quality control in your batch or process mixing. This will take one of the variables out, and one that is commonly overlooked. So, ask yourself if you have any mixers that are simply overlooked, and give us a call. Your mixing should achieve uniformity in a set time. Mixers are process equipment, they need to work within the confines of time, quality and money.

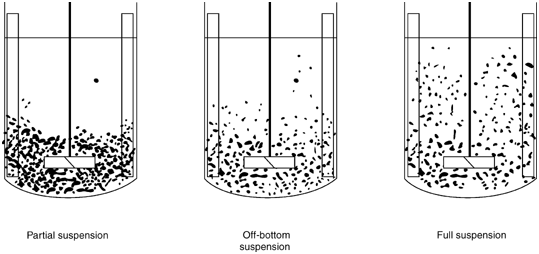

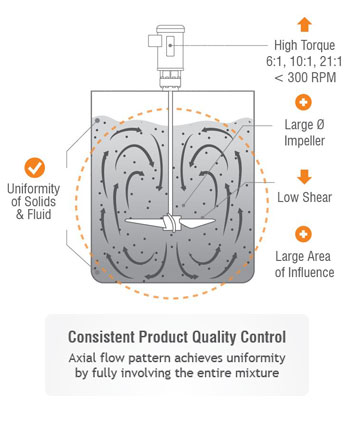

Generally, there are two main types of mixing applications: Blending and Solid Suspension. Blending, by definition, is the mixing of two miscible materials to make a uniform solution. Solid suspension, by definition, is suspending solid particles uniformly in fluid. With both situation the main goal is to attain product uniformity. To Dynamix the level of product uniformity equals mixing quality.

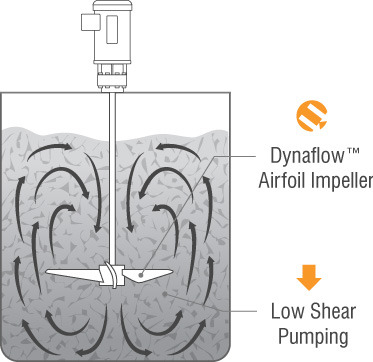

Blending Time to complete mixing can be controlled by understanding Torque and Pumping. Yes, I said that right, Pumping. A mixer is a pump and when you can look at it in this way you begin to understand the controls and approaches we take to design and configure our mixers. At Dynamix we consider the optimum mixing intensity (Pumping/Flow) needed during the axial flow, given various parameters: superficial velocity, annular velocity and specific gravity of the fluid and solid if applicable.

Be ready to answer a few questions, but also be ready to gain control of this critical element of your operations. Dynamix applications engineers are trained in the science of mixing, call us today to get the best configuration for your application needs.

Note; we are also offering full training in this, as well as application and process specific training in Mining, Pulp and Paper, Water Treatment. Call and ask our Sales Manager Manoj Dabir to schedule one.