Agitator Design for Wastewater Clarification – Part 2

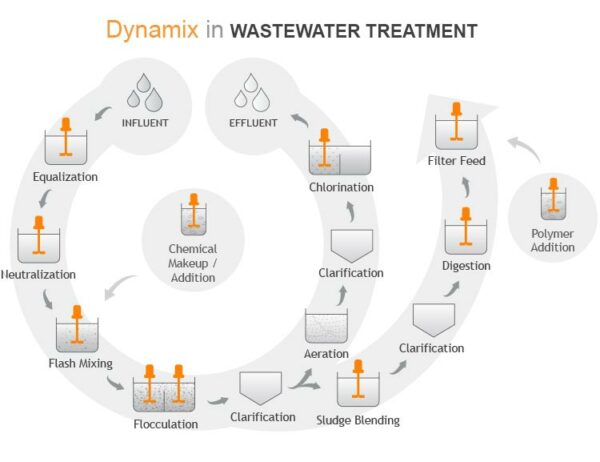

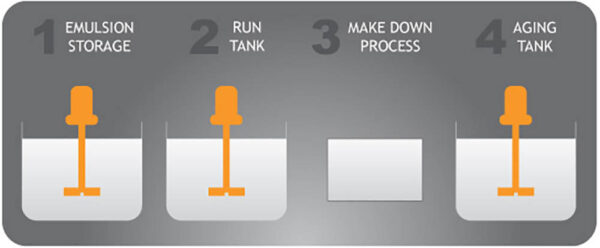

Clarification on Flocculation In our previous article, Agitator Design for Wastewater Clarification Part 1, we looked at how to optimize a mixer for the unit process of coagulation. In wastewater treatment, coagulation is normally followed by flocculation. While coagulation is used to destabilize and agglomerate suspended waste particles, flocculation brings the colloids out of suspension in the form of floc, and allows the particles to be more readily removed from the water stream. In this article, we will examine the process of flocculation, the flocculator mixer, and how mixer parameters change to achieve the desired result. Flocculation Following the coagulation of destabilized microscopic particles in wastewater, the process of flocculation encourages the newly formed micro-floc to stick together, making even larger clumps