Mixing 101: Torque and the Art of Mixing

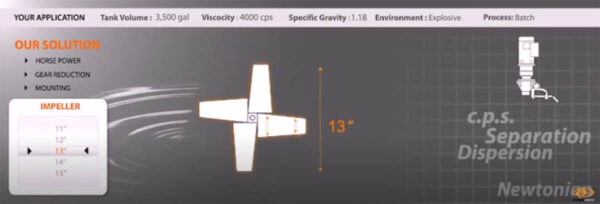

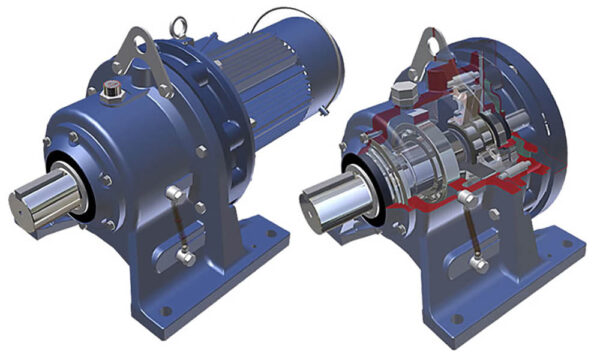

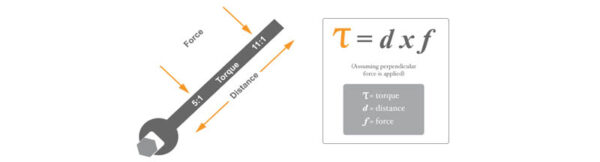

What is torque… and what does it have to do with mixing? Selecting a mixer drive with a high horsepower rating doesn’t guarantee a satisfactory result in your application, and it doesn’t necessarily translate into a more powerful mixer either. Horsepower is merely a measurement of the rate at which work is done – or how much input power a motor has. Simply throwing more horsepower at an application may make a mixer’s impeller turn faster, but it will also drive down efficiency, negatively impact your budget, and can even damage your product through shear. If the driving force of a mixer is rotational, then horsepower is secondary to torque as the force that drives the pumping and performs the