Mixing 101: Air vs. Electric

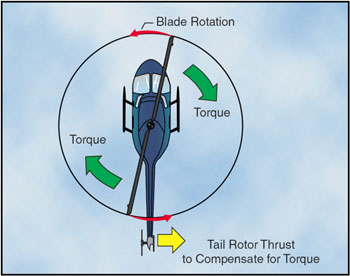

5 FACTORS FOR OPTIMAL MOTOR SELECTION Air or electric? End users often don’t understand all the factors to consider when making the decision to use an air motor vs. an electric motor in their mixer configuration. While a mixer’s motor type is largely determined by the plant environment, the value of considering several important factors is substantial when each consideration point is thoroughly understood. A proper understanding of torque, energy efficiency, variable speed, mixing environment, and mixer weight are all significant and valuable considerations to discuss when selecting an appropriate motor. In a real-world example, our engineers leveraged these factors when working with a leading car manufacturer, and the decision to make a wholesale change within their production environment not